How Sealing Gaps Under IT Racks Can Lead to Significant Savings8 min read

In previous articles we’ve discussed the importance of sealing gaps both within IT racks as well as gaps between IT racks in order to optimize your data center’s cooling and ultimately reduce operating costs. What we haven’t talked about are the gaps commonly found under IT racks, which due to their inconspicuous location, are often left unsealed. If not addressed, these gaps can potentially be extremely harmful to IT equipment, leading to costly capital expenditures down the road.

The Need for a Solution

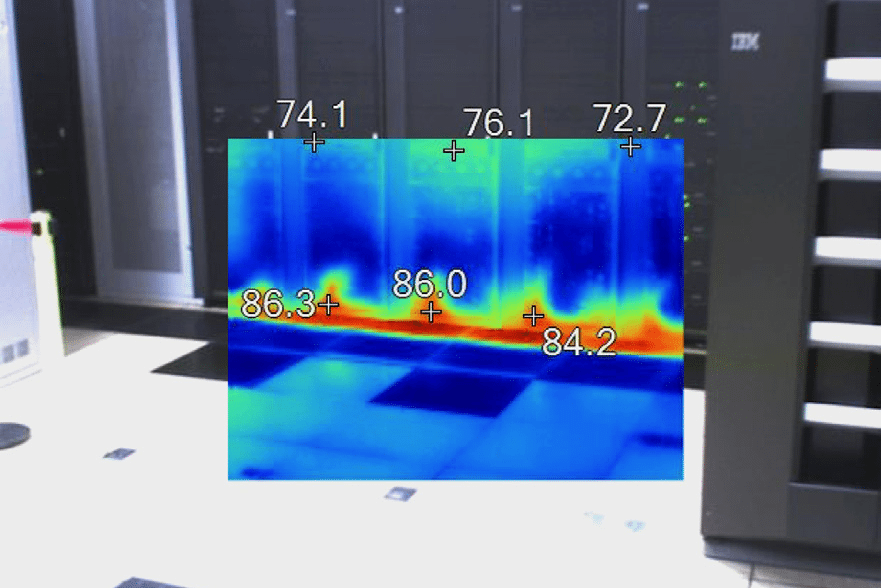

Often overlooked, the small space between the bottom of an IT rack or cabinet and the raised floor or slab can have a significant impact on IT inlet temperatures. This space allows for exhaust air recirculation, as air from the hot aisle flows under the racks into the cold aisle where IT equipment at the bottom of racks pulls in the hot air. This leads to hotspots, which can ultimately lead to degradation of IT equipment. Since we recently enhanced our AisleLok® Under Rack Panel, we conducted a computational fluid dynamics (CFD) analysis using Future Facilities’ 6 Sigma software to examine the effectiveness of sealing these gaps.

The CFD analysis revealed the impact of sealing these small gaps, which reduced temperatures as a result of eliminating the exhaust air recirculation under the rack. Furthermore, sealing the gap under the rack created opportunities to improve overall airflow management efficiency and increase cooling capacity by raising temperature set points and reducing fan speeds.

The Results

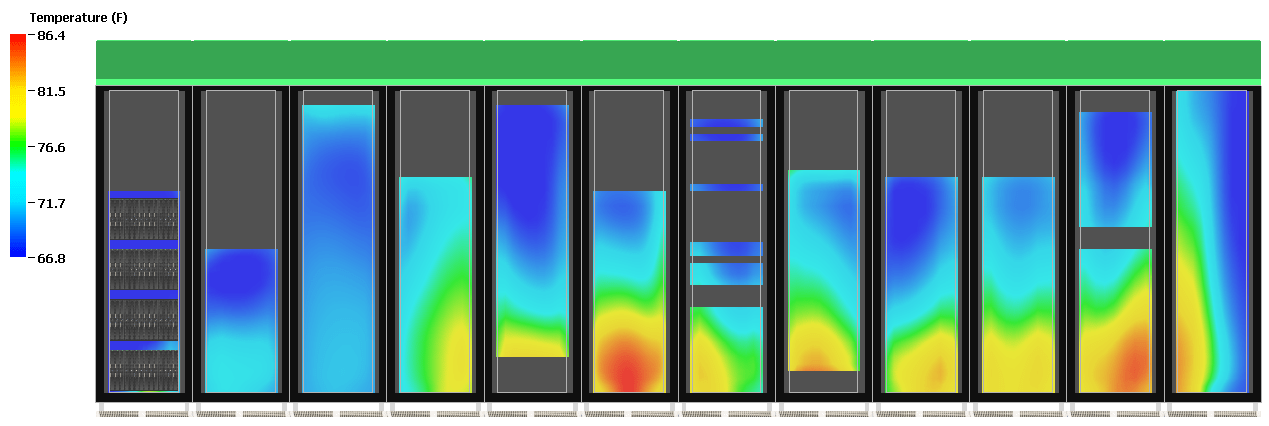

This image shows the variation in IT equipment intake air temperatures across a row in the CFD model. The dark gray areas are where blanking panels fill locations without IT equipment. The maximum IT inlet temperature is 86.4° F.

BEFORE (Unsealed openings underneath IT cabinets)

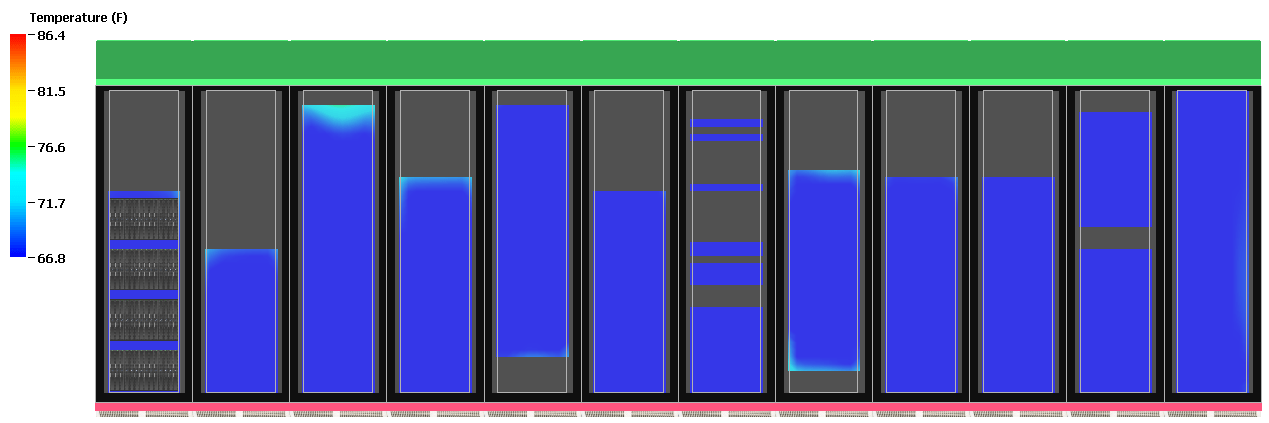

The next image shows the dramatic improvement in IT equipment intake air temperatures across the same row after installation of Under Rack Panels. The maximum IT inlet temperature is 75.0° F, a reduction of 11.4° F.

AFTER (openings under IT cabinets sealed with AisleLok Under Rack Panel)

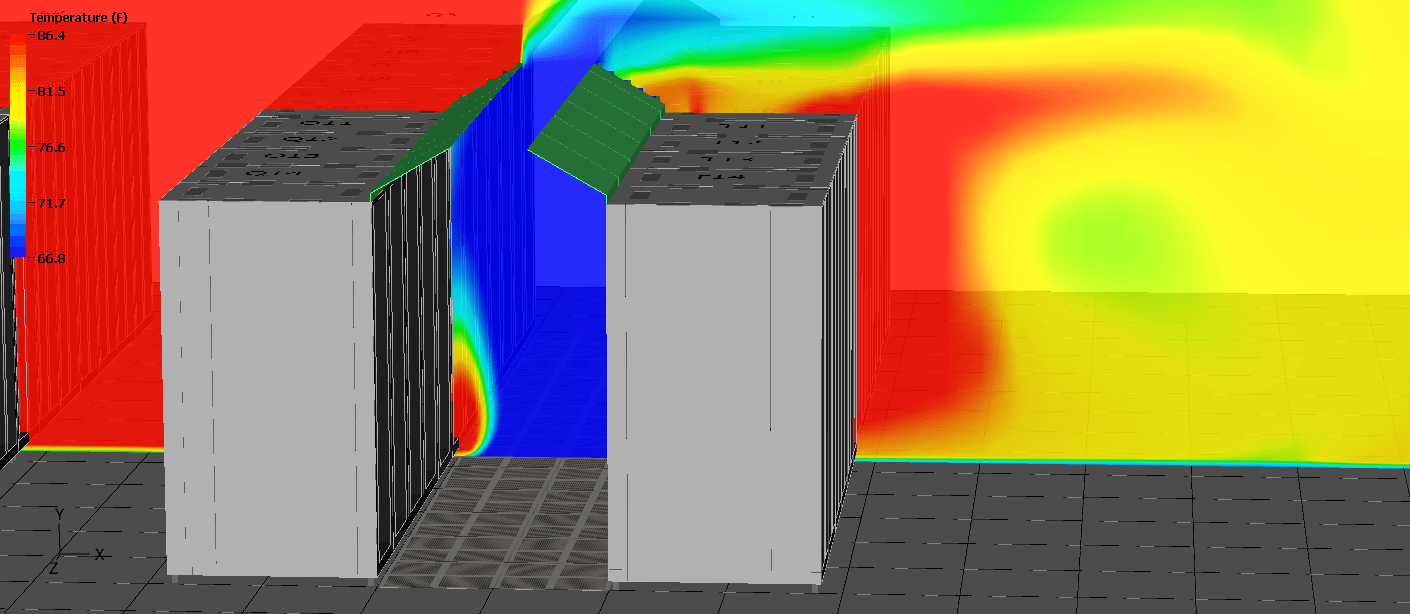

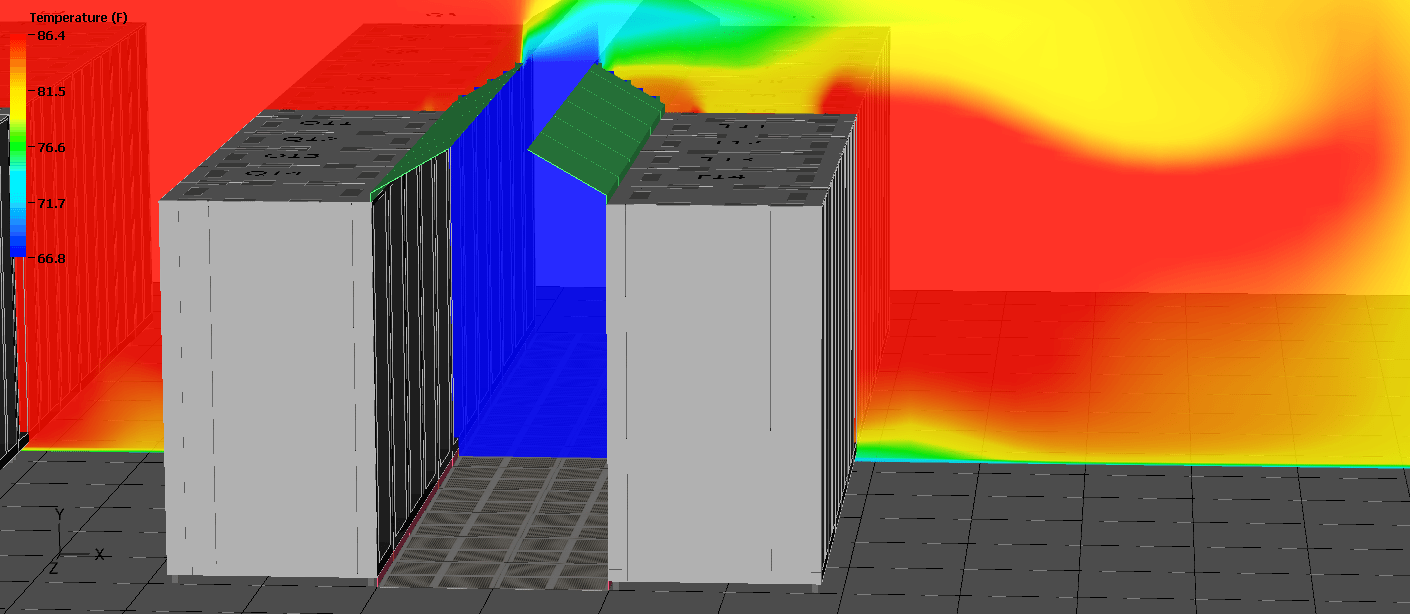

The image below clearly shows why intake air temperatures are much higher with gaps under the racks: hot exhaust air is flowing from the hot aisle under the racks and into the cold aisle. The hot exhaust air coming from under the racks prevents the conditioned air supplied by the tiles in the cold aisle from reaching the equipment in the bottoms of the racks.

BEFORE (unsealed openings underneath IT cabinets)

Sealing the space under racks with AisleLok® Under Rack Panels prevents hot exhaust air from flowing into the cold aisle. The conditioned air supplied by the tiles in the cold aisle can fill the space and support the IT equipment from the bottom to the top of the rack.

AFTER (openings under IT cabinets sealed with AisleLok Under Rack Panel)

Conclusion

Under Rack Panels, like the AisleLok® Under Rack Panel, can dramatically reduce the intake air temperature of IT equipment. The maximum IT inlet temperature reduction in the model was 18.9° F. The average maximum IT inlet temperature reduction for all the cabinets in the modeling was 10.5° F. Holistic airflow management, including sealing the gaps under racks, is crucial to achieving the lowest and most even IT equipment intake air temperature distribution. Achieving low and even IT equipment intake air temperatures allows for the greatest reduction in operating cost and increase cooling capacity by adjusting the cooling controls. Modeling of fan speeds showed the ability to reduce fan speeds by 10% resulting in energy savings of $5,318 annually for the small 2,260 sq. ft. computer room (@$0.10/kWhr). This equates to $47,059 of annual energy savings for a 20,000 sq. ft. computer room. Based on MSRP cost for the Under Rack Panel simple payback is achieved in less than 2 months.

1 Comment

Submit a Comment

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

Lars is correct, all the gaps around the cabinet should be sealed as far as possible to stop are escape and hot/cold air contamination. If you look at the Minkels cabinet you will see this is something we have been doing for a number of years , the plinths at front rear and side sit flush to the floor. When choosing a cabinet is it also worth looking at how they bay together, some cabinets do not bay tight but leave a gap the height of the cabinet allowing air from the aisle to escape. We spend hundreds of pounds on servers is enough time spent looking at monies lost due to inefficient cooling in poorly designed housings?