Aisle Containment Strategies: Finding the Right Balance11 min read

This post originally appeared on Networks Europe, in an article titled Optimising Airflow and was contributed by Damian Stackhouse, Managing Director of Upsite partner, EDP Europe. You can view the original article here on p. 34-35.

It’s widely recognized that data centers consume almost as much energy to cool them as they do to power the IT equipment that they house, with many using up to four times more cooling than is required. By improving cooling efficiency, and how the conditioned air is delivered to the IT equipment, significant savings can be made and extra capacity found.

The American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) works closely with manufacturers to determine the optimal performance temperatures for their equipment, producing recommendations and industry guidelines on the ideal conditions for installed IT equipment. These guidelines now suggest that IT equipment can work effectively at higher temperatures than previously thought, enabling the supply air to be increased, even to as high as 27°C. Some studies have shown that for every degree Fahrenheit (0.56°C) that the set point on a CRAC unit can be raised by equates to a 4% energy cost saving. And since cooling costs are almost as high as powering the equipment, raising cooling set points can result in major energy cost savings.

In order to operate within the recommended temperature ranges put forward by organisations like ASHRAE, any business that operates a data center (enterprise or co-location) must have implemented a defined airflow management strategy. Optimizing airflow can help with delivering a number of key benefits including improving efficiency, extending the life of IT equipment and driving cost savings. In order to help achieve the optimal performance of a data centre’s cooling system, there are a number of steps that should be taken either sequentially or concurrently as part of an overall cooling & efficiency strategy. These steps include the implementation of basic, low cost hot/cold air segregation best practices at a raised floor & rack level, including sealing holes in the raised floor, blanking unused HU spaces between rack-mounted IT equipment, and working up to more significant investments at a room level that can include aisle containment solutions. Airflow optimisation should be part of any new data centre design brief, as well as forming part of efficiency and sustainability initiatives across legacy data centres.

Beyond the basic raised floor and rack airflow management best practices, aisle containment systems create a physical barrier preventing the mixing of hot and cold air within a computer room or data centre hall. This is achieved by either, enclosing the cold aisle which feeds the IT equipment – cold aisle containment (CAC), or containing and removing the warm air that has been exhausted from the IT equipment – hot aisle containment (HAC). As part of a holistic approach, the implementation of aisle containment contributes to a greater level of control, which in turn allows significant improvements in the performance of the data centre environment as a whole while realising cost savings. If set points can be increased, CRAC unit fan speeds slowed down or CRAC units switched off altogether, data centre managers are able to find additional capacity within the same footprint, which can facilitate the deployment of more IT equipment and additional revenues being generated or services provided.

The Contained Data Centre

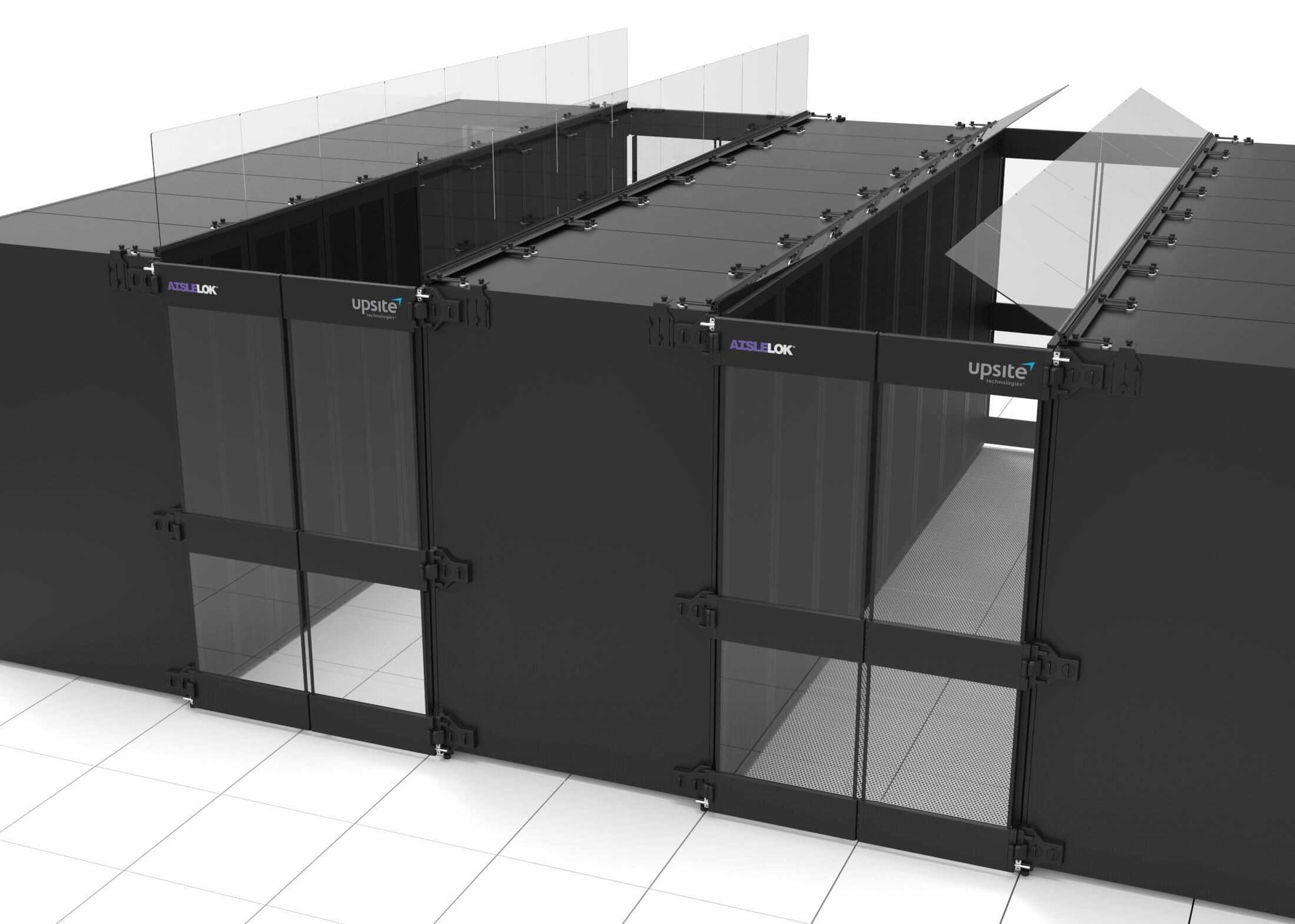

Within a contained data centre environment, end-of-aisle doors are normally used to prevent air mixing at the end of rows of cabinets. Roof systems can also be deployed to enclose the cold aisle completely. A number of different roof systems are available including fixed, passive drop away, or active roofs that are connected directly to a data centre’s fire suppression system and are triggered to pivot in an alarm state.

Aisle containment systems don’t need to be rack manufacturer specific. In fact, some of the most flexible containment solutions are available from companies that specialise in bespoke aisle containment systems tailored to the clients’ individual needs and data centre configuration. These can be retrofitted or used in new build applications irrespective of the brand of racks being used immediately, or in the future. Such systems are fully flexible and can be designed to fit with any rack configuration including aisles with varying rack heights, widths, depths and alignment. Even obstacles such as building column supports can be incorporated into the solution, as well as overhead power and data services, fire suppression, and security systems. The construction can be from steel, with Perspex or polycarbonate infill panels, or produced entirely from PVC curtains if a lower-cost or more temporary solution is required.

Full or Partial Containment

Until recently it was thought that for aisle containment to work effectively, the aisle had to be fully enclosed or sealed with air leakage rates of less than 3%. However, the recent introduction of an out-of-the-box modular containment solution alters this perspective. The solution consists of bi-directional doors and roof top baffles that attach to the racks in a non-intrusive way using magnets. The rack top baffles only partially seal the aisle, but in a recent white paper comparing full containment to partial containment, it concluded the difference in performance between the two was minimal. The report found that there was about 1°C difference in the average inlet temperature with the partial containment being slightly warmer, and the partial system enabled a reduction in CRAC energy usage by 30% – only 5% less than that achieved by the fully enclosed system. The partial system gave the biggest return on the cost of installation and reduction in the time to deploy the solution. And being modular it can be easily reconfigured when racks are added or removed from a row, or if a data centre is closed down and equipment migrated to a new facility.

Finding the Right Balance

Installing an aisle containment solution, whether it’s a fully enclosed or partial system still requires on-going airflow management to obtain the best long-term results. Bypass airflow, or the conditioned air that doesn’t pass through the IT equipment to cool the micro-chips, will still be present unless CRAC units are correctly balanced to provide the right amount of cold air needed to cool the IT equipment. If cold air is over-supplied to the contained aisle the excess conditioned air will escape through small gaps or get pushed through the IT equipment. The correct balance can only be achieved by reducing fan speeds and raising set points. It’s these changes that enable a reduction in operating costs, help reduce carbon emissions, extend the lifetime of equipment and provide the maximum return on investment.

Every data centre will have its own set of design constraints & considerations which will shape its airflow management strategy and, ultimately determine which aisle containment solution, if any, is most suitable for achieving the outcomes required by the business it supports. The good news is that there are a range of flexible systems available to suit the needs of any data centre targeted for improvement, so don’t hesitate to implement your airflow optimisation strategy.

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

0 Comments