How Modular Containment Impacts Intake Air Temperatures and Hotspots8 min read

As we’ve previously discussed, exhaust air circulation is one of the biggest problems a data center can face regarding its cooling and airflow strategy because it can lead to high intake air temperatures and hotspots. If not addressed, these issues can be very costly to your data center by reducing the reliability of IT equipment and/or resulting in high energy costs. Determining the areas where exhaust air circulation are occurring and properly addressing those areas with the appropriate airflow management initiatives is essential to maintaining the efficiency of your data center’s cooling infrastructure and ensuring the health of IT equipment.

While exhaust air circulation can occur in many areas throughout a data center, two of the largest areas it can occur are over the tops of cabinets and around the ends of aisles. The best way to combat these problem areas is to implement containment. Now, it’s important to note that containment on its own can be very effective, but it’s imperative to manage other problem areas such as open U spaces or gaps under IT cabinets to achieve the best results. Nevertheless, containment has become the most common best practice to eliminate exhaust air circulation over the tops of IT equipment and around the ends of aisles.

Enter, Modular Containment

AisleLok® Modular Containment is the industry’s first containment solution that can be applied on a per-rack basis and can be moved and reused as the computer room evolves. Its magnetic application allows for self-installation in just minutes without the use of tools. It provides the core benefits of legacy containment for about half the cost.

Compared to legacy containment solutions, implementing AisleLok® Modular Containment in a data center is a low cost solution to airflow management and improved data center performance. The upfront cost to install is low as there is no need for specialized 3rd party planning and installation services. It can be installed utilizing in-house IT support personnel with little disruption and virtually no risk to the data center. It is also fast to install; the components are a tool less design and attach directly to the cabinets without additional hardware or modifications to the cabinet.

AisleLok® Modular Containment also has significantly lower overall costs due to the modularity of the system. Cabinets, aisles and rows can be reconfigured as the data center needs change. The modular containment system can adapt without disrupting data center operations of incurring the cost of specialized planning and installation services. In many data centers AisleLok® Modular Containment can provide most of the benefits of legacy containment, at a lower initial and overall cost, while maintaining the flexibility to grow and change as the data center configuration and requirements evolve.

Case Study

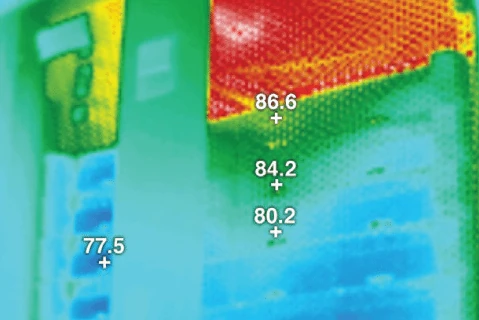

The effectiveness of AisleLok® Modular Containment was recently tested by CyrusOne®, a large colocation provider. CyrusOne® was experiencing multiple hot spots despite the abundant supply of conditioned air via the existing 56% open area grills. It was determined that one of the leading factors contributing to the hot spots was hot air wrapping over the tops of cabinets and around the sides of the end-aisle cabinets. In order to combat these issues, they implemented AisleLok® Modular Containment which included 8” Horizontal Rack Top Baffles and Bi-Directional Doors.

After implementation, CyrusOne® was able to reduce the maximum intake temperature by 7° F (3.9° C). The data center manager was pleased to see the immediate impact of the solution, saying “The impact of containing the row with AisleLok® Modular Containment could be felt immediately. We quickly saw that the baffles stopped the exhaust air from entering servers on top of the rack, and the Bi-Directional Doors prevented air from wrapping around the end-of-aisle cabinets. The drop in temperatures was immediate.” Additionally, the number of hot spots in the row decreased from six to two after the implementation of AisleLok® Modular Containment. These improvements were achieved without increasing the flow rate of conditioned air or reducing the temperature of the conditioned air.

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

0 Comments