Rack Airflow Management: More Than Just Blanking Panels9 min read

What if I told you that you could trim your annual IT energy costs by only improving airflow management inside your data center equipment cabinets? Sealing open U spaces as well as addressing the commonly overlooked gaps between the edge of the IT cabinet and servers can increase the effectiveness and efficiency of your cooling infrastructure. By enabling you to make adjustments to the cooling infrastructure, such as reducing fan speeds or increasing temperature set points, these airflow management improvements often yield enough energy savings to pay for themselves within the first year.

One important thing to point out is that the goal of all airflow management initiatives is to improve the intake air temperatures to IT equipment. More specifically, to reduce the highest intake air temperatures so that all intake temperatures are as low and even as possible. This, in return, enables changing the control of cooling infrastructure to improve efficiency and increase capacity. In order to achieve these goals, there are many steps along the way that need to be taken in order to optimize airflow and thermal management. One thing to keep in mind is optimization is a process, not an event. Our 4 R’s Methodology provides a protocol to follow in order to achieve this process. Just as a reference, the 4 R’s are: 1. Raised Floor, 2. Rack, 3. Row, and 4. Room. The topic of this discussion refers to the second R, managing airflow at the Rack level.

Identifying Bypass Airflow and Exhaust Air Circulation

Bypass airflow at the rack level refers to any supply air that passes through open U spaces or around IT equipment and returns to the cooling unit without ever passing through the servers. While open U spaces are commonly addressed with blanking panels, the gaps between the edge of the IT cabinet and the server rails are commonly overlooked. In a typical 28” wide cabinet, these gaps amount to about 1/3 of the total area at the face of the cabinet, a significant area for bypass airflow to occur. In addition, depending on the flow rate, these same areas can allow for exhaust air circulation, which in turn can contribute to hot spots, threatening the health of IT equipment.

Addressing Problem Areas

Installing blanking panels is a common best practice to seal open U spaces within the rack. While less common but just as important, installing air dam kits such as our HotLok® Rack Airflow Management (RAM) kit addresses the gaps between the sides of cabinets and server rails. Making these improvements addresses these problem areas to effectively seal the vertical plane at the face of IT equipment, allowing you to increase temperature set points, reduce fan speeds, or even turn off unneeded cooling units. In addition, these improvements decrease overall system energy consumption, wear and tear on the equipment, and cost of the recurring maintenance program. The investment you put into improving airflow often pays for itself via energy savings. These energy savings will continue year over year, and more than justify the investment in making airflow management improvements. It is important to remember that every bit of cold air that is prevented from escaping to the hot aisle improves system performance, saves energy costs, and recovers stranded cooling capacity.

A Proven Solution

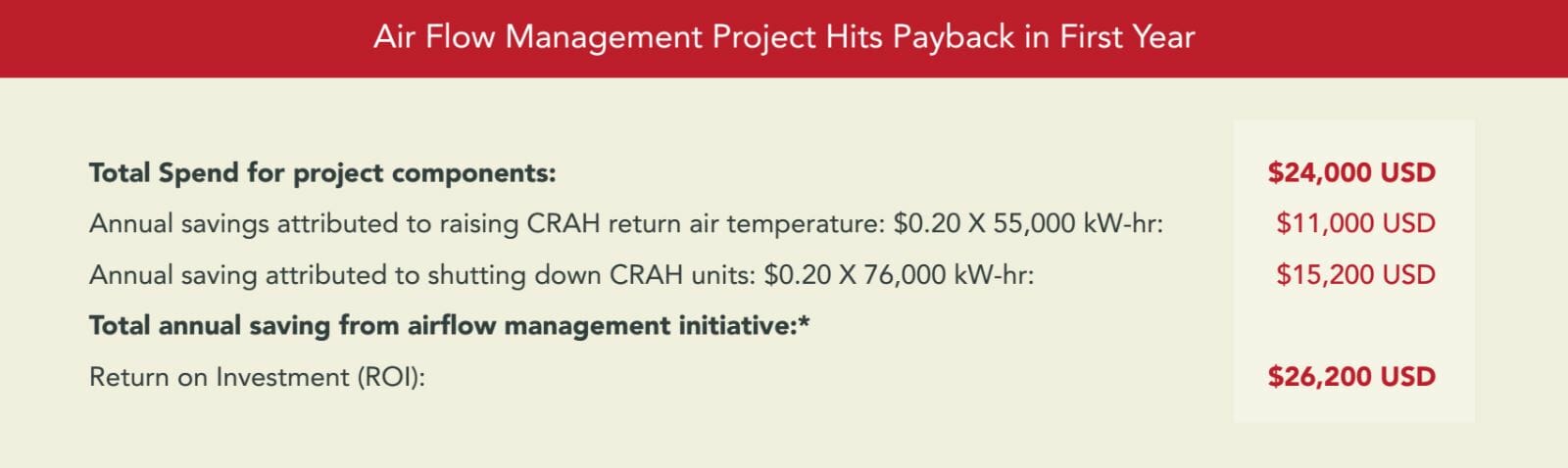

Recently, a Fortune 50 US-based Commercial Bank in Japan trimmed an equivalent of 5.5% of their annual energy costs with an initiative that simply improved airflow management inside the data center equipment cabinets using HotLok® products. Their computer room had 270 kW of IT load but was running 450 kW of CRAH capacity. This attempt to avoid hotspots and provide the proper cooling the IT equipment required resulted in a Cooling Capacity Factor (CCF) of 1.5 (an ideal CCF is 1.2 or lower). This clearly indicated an opportunity for improved efficiency. The problems were not due to a lack of capacity, but rather a lack of airflow management. The high cost of energy in the data center’s location (Tokyo) made efficiency improvements a high priority. A short time after implementing our HotLok® Rack Airflow Management (RAM) Kit, the environment stabilized making it possible for them to increase the return air temperature setpoint by 3.6° F (2° C) and two CRAHs were shut down. The determined energy savings from shutting down two CRAHs and increasing temperatures alone will save the bank $26,000 USD annually. The total project cost was about $24,000 USD, so all improvements will pay for themselves in less than a year.

The HotLok® Rack Airflow Management (RAM) Kit from Upsite Technologies is a valuable addition to HotLok® Blanking Panels. A typical 28 inch (700 mm) wide rack (cabinet) has 19 inches (465 mm) between mounting points on the equipment rails, and 9.3 inches (235 mm) in the cabinet outside the rails (about 4.5 inches (118 mm) on each side). The HotLok® RAM kit covers approximately 1/3 of the inside face of the cabinet that installed servers and blanking panels leave open.

Key Findings from the Case Study

In addition to the $26,000 annual direct savings, indirect savings resulted from improved chilled water system efficiency, increased life span for all cooling units, and reduced maintenance. Furthermore, there will be additional savings from deferred capital expenditure for additional cooling units that would have been required to support additional IT growth.

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

0 Comments