What You Need to Know About Row Airflow Management20 min read

To put it simply, managing airflow at the Row level refers to improving cold aisle and hot aisle separation, and is typically done once you’ve made improvements at the Rack level (e.g. blanking panels) and Raised Floor level (e.g. brush grommets). While many people quickly navigate to containment when discussing row airflow management, it’s important to note that there are other areas in the row that need to be addressed when managing airflow at this level. Furthermore, when it does come to containment, knowing the solutions that are available to you and being able to identify what type of containment is best suited for your data center will help you not only save time, but also money.

Before we jump into the specifics, one thing to point out is that the goal of all airflow management initiatives is to improve the intake air temperatures to IT equipment. More specifically, to reduce the highest intake air temperatures so that all intake temperatures are as low and even as possible. This, in return, enables you to make changes to the controls of the cooling infrastructure, such as increasing temperature set points, lowering fan speeds, or in many cases, turning cooling units completely off. Making these changes is the key to achieving many of the benefits of airflow management, like improved efficiency, increased capacity, and reduced operating costs. To maximize these benefits, managing the airflow at all levels in the data center (Raised Floor, Rack, Row, and Room) is very important.

Row Airflow Management Best Practices

As noted above, Row airflow management refers to improving cold aisle and hot aisle separation. To do this effectively, there are a few areas that need to be addressed:

- Block open spaces underneath cabinets. You might not think it, but the small space between the bottom of an IT rack and the raised floor/slab can play a profound role in airflow management and on IT equipment intake temperatures. Usually ranging in size from half an inch to two inches, this space allows IT equipment exhaust air to travel underneath the rack and ultimately back into the IT equipment air inlets. This is referred to as exhaust air recirculation and when it occurs, can cause several problems for the data center: increased intake temperatures, hot spots, and a likelihood of IT equipment failure in the long-term if the issue is not addressed. All of this will require more cooling units to be running or fan speeds to be higher than would otherwise be necessary. It also necessitates lower cooling unit temperature set points to overcome the mixing and keep your IT equipment intake air temperatures within the desired limits. To address this, blocking off these open spaces with under rack panels is an easy and cost-effective solution that can have a profound impact on reducing IT equipment inlet temperatures.

- Seal spaces in cabinet rows where there are missing cabinets or gaps between cabinets. This may seem like an obvious point, but there are many cases where large gaps in between cabinets are present (either due to a building column or a cabinet that has been removed) and have not been sealed off. Sealing these gaps is very important for a couple reasons. Similar to gaps underneath racks, exhaust air recirculation can occur, which as we know will increase IT equipment intake temperatures and reduce your equipment’s reliability. Secondly, a large volume of conditioned supply air can be lost, a phenomenon referred to as bypass airflow. This is when any amount of supply air bypasses IT equipment and returns to the cooling unit unutilized. Similar to exhaust air entering the cold aisle, the loss of conditioned supply air requires more cooling units to be running or higher fan speeds to overcome the loss of conditioned airflow volume. To address this issue, blocking off any open space in between cabinets, whether it’s just a couple inches or a few feet, with rack gap panels or sealing foam will dramatically impact IT equipment intake temperatures at a reasonable cost.

- In cases where there is a missing cabinet at the end of an aisle, causing uneven aisle lengths, there are innovative solutions available to address this issue. Referred to as an adjustable mounting post, this simple solution provides a structural support surface to shore up uneven rows by enabling the attachment of rack gap panels and aisle-end doors.

- Contain the ends of aisles with doors on either the hot or cold aisles. This is where we jump into containment, but we’re purposely breaking out aisle-end doors here because they can be extremely effective on their own. In fact, cabinets at the ends of rows are the most vulnerable to increased IT equipment intake temperatures because of the large potential for hot exhaust air to wrap around the ends of rows. Whether applied to hot aisles or cold aisles, you will still reap the benefits of aisle-end doors by effectively eliminating exhaust air recirculation in this area. There are many door solutions available that range in price, but the real cost savings benefit with this practice is avoiding the cost of full containment. Whether containment is something you are doing in phases or simply a budgetary decision, aisle-end doors are an effective solution that can be applied in singularity and still be extremely effective in reducing IT equipment intake temperatures.

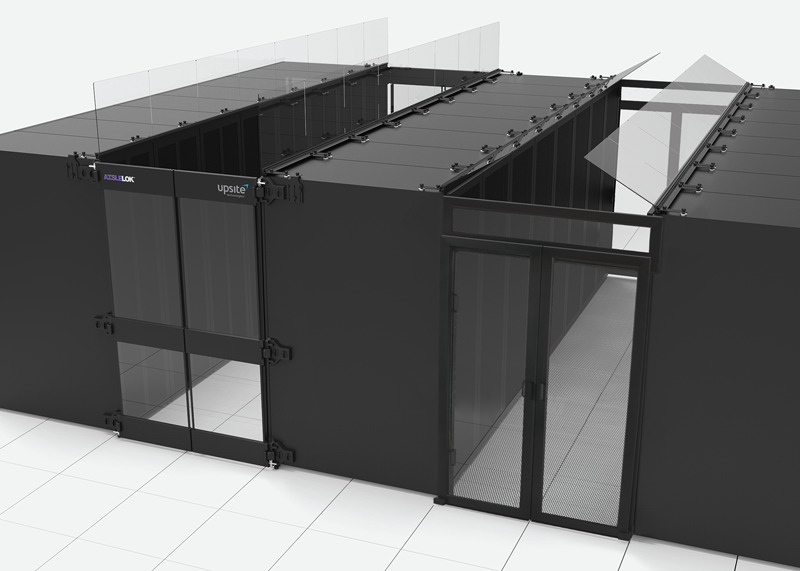

- Contain the tops of cabinets on either the hot or cold aisles. This is the next step in containment and is typically deployed in situations with high cabinet densities or when the highest possible efficiency is desired. In cold aisles, this involves some form of partitions, baffles, or roof over the cold aisle to contain conditioned supply air. In hot aisles, this involves a configuration of baffles or duct work from the hot aisle to the returns of the cooling units to effectively direct and contain exhaust air. As with doors, there are many solutions available that range in price, however unlike doors, the styles of options can vary greatly. In most cases, full containment (full roof over cold aisles or complete duct from tops of hot aisles to cooling unit returns) is unnecessary. Either angled baffles for cold aisles or vertical baffles for hot aisles are the most cost-effective solutions that will significantly impact IT equipment intake temperatures.

Saving on Installation Costs with Modular Solutions

For many airflow management improvements, especially aisle containment, it has long been necessary to hire a 3rd party crew for installation. Thankfully, in recent years the further development of aisle containment and other airflow management solutions has led to breakthroughs that have eliminated the need for 3rd party installation. This has come in the form of magnetic attachments for solutions that address all of the best practices listed above: under rack panels, rack gap panels for gaps within rows, aisle-end doors, and rack top baffles. This is a significant cost savings opportunity that leads to a much quicker ROI for impactful airflow management improvements.

Secondly, due to their magnetic attachments, these airflow management solutions are modular in nature and can be uninstalled and reinstalled at will, rather than being a fixed installation. As we all know, data centers are dynamic environments that can change and be reconfigured. Having the flexibility to also reconfigure your airflow management solutions as your data center evolves is not only convenient, but can also save on removal and reinstallation costs down the road.

Matching Cooling Capacity with IT Load

Airflow management alone does not save you any money on cooling energy costs, instead it improves IT equipment intake temperatures and enables you to make changes to the cooling infrastructure. Reason being, if you have implemented these airflow management solutions correctly, you should now have an excess of conditioned supply air in your cold aisles because there is no longer any mixing of exhaust air with conditioned air, and vice versa. The next step is matching the cooling required by the IT load with what is being supplied by the cooling units. This can be in the form of raising set points, lowering fan speeds, or turning cooling units off altogether. This is an iterative process that should be taken in incremental steps with constant evaluation of IT equipment intake temperatures. This process of optimizing the cooling infrastructure is what is referred to as Room level airflow management, and will be the topic of the next article in this series.

Conclusion

Row level airflow management is not all about containment. There are many holes and gaps in the row such as underneath cabinets and in between adjacent cabinets that need to be sealed to manage airflow at the row level effectively. In situations when cabinet densities are high enough, or the highest possible efficiency is desired, hot or cold aisle containment is necessary, but this doesn’t mean full containment is your only option. Partial containment in the form of only aisle-end doors is an extremely effective strategy to reduce IT equipment intake temperatures. Furthermore, when top of rack containment is necessary, modular baffles is a cost-effective solution that is just as impactful as a full roof or duct work in cold or hot aisles, respectively. Lastly, stay abreast of innovative solutions for row level airflow management that utilize magnetic attachments. These solutions will give you the biggest cost saving opportunities by reducing or eliminating installation costs altogether.

The original version of this article was published on MissionCriticalMagazine.com, titled Managing Airflow at the Row Level. You can view it here.

The industry's first and only tool-less containment solution!

AisleLok® is the industry’s first modular containment solution,

proven to provide the core benefits of containment with greater flexibility and value.

The industry's first and only tool-less containment solution!

AisleLok® is the industry’s first modular containment solution,

proven to provide the core benefits of containment with greater flexibility and value.

0 Comments